Methods and Equipment for Battery Testing

Highlights:

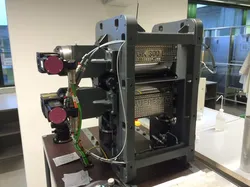

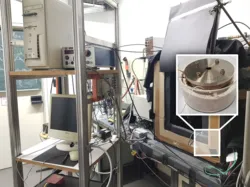

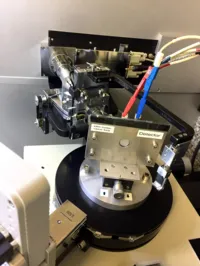

- Home-made cell setup for ASSB Application

- Precisely adjustable pressure by compression of a spring; pressure range from 10 – 120 MPa

- Enhanced sealing technique by a membrane bellow

- Investigation of conductivity of solid electrolytes and cycling performance of solid state battery cells under varying pressure

Gloveboxes are an essential equipment for battery assembly. Inside the glovebox, there is an inert Argon atmosphere to protect the cells from detrimental reactions with moisture, O2 or CO2 from ambient air while being assembled. In this glovebox, there are two important tools for building battery cells: a vacuum-sealing device for pouch cells (left side) and a crimping tool for CR2032 coin cells (right side). In the red box on the right side, the components of a coin cell are shown as well as an assembled one inside the cell holder as it is used for electrochemical testing.

Highlights:

- Potential-resolved monitoring of the gas evolution in an electrochemical cell (e.g., graphite//NMC)

- Investigation of reaction mechanisms of electrolyte additives with gaseous decomposition products

- Characterization of active material degradation

- Two-compartment cell design with a sealed Li-ion conducting membrane avoids electrode crosstalk

References:

- M. Metzger, C. Marino, J. Sicklinger, D. Haering, H.A. Gasteiger, Journal of the Electrochemical Society, 162 (7) A1123-A1134 (2015)

- N. Tsiouvaras, S. Meini, I. Buchberger, H.A. Gasteiger, Journal of the Electrochemical Society, 160, A471-A477 (2013)

Highlights:

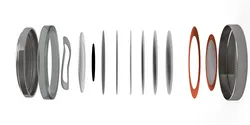

- Operando monitoring of the lithium concentration across battery electrodes with (sub-)micrometer spatial resolution

- Quantification of the lithium concentration distribution as function of depth

- Operando cell performance comparable to a standard laboratory cell

Reference:

- F. Linsenmann, M. Trunk, P. Rapp, L. Werner, R. Gernhäuser, R. Gilles, B. Märkisch, Z. Révay, H.A. Gasteiger, J. Electrochem. Soc., 2020, 167, 100554 - DOI

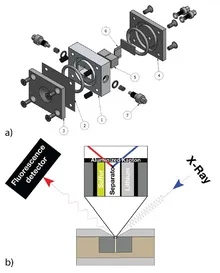

Highlights:

- Spatially-resolved operando X-ray absorption spectroscopy (XAS) of the electrodes and the electrolyte-soaked separator

- Monitoring of intermediate species during battery charge/discharge, e.g., polysulfides in Lithium-sulfur battery

- Investigation of the transition metal dissolution and deposition in Li-ion batteries

- Characterization of the potential dependence of hydrogen absorption into a Pd/C catalyst for hydrogen oxidation reaction (HOR) in fuel cells

References:

- Y. Gorlin, M.U.M. Patel, A. Freiberg, Q. He, M. Piana, M. Tromp, H.A. Gasteiger, Journal of the Electrochemical Society, 163 (6) A930-A939 (2016) - DOI

- J. Wandt, A. Freiberg, R. Thomas, Y. Gorlin, A. Siebel, R. Jung, H.A. Gasteiger, M. Tromp, Journal of Materials Chemistry A, 4, 18300-18305 (2016) - DOI

- A. Siebel, Y. Gorlin, J. Durst, O. Proux, F. Hasché, M. Tromp, H.A. Gasteiger, ACS Catalysts, 6 (11), 7326-7334 (2016) - DOI

Highlights:

- Application of pouch cells for large working electrodes with a geometric area of 9 cm2 (30 × 30 mm2) versus counter-electrodes (geometrically oversized, 33 × 33 mm2)

- Monitoring cycling performance in half- and full-cell configuration

- Application of different pressures for cell compression between 3 and 70 bar depending on application

- Implementation of a quartz glass window for an Operando UV–vis pouch cell design

- Post-mortem analysis of cycled electrodes (e.g. BET, half-cell tests, EIS)

References:

- Capacity Fading Mechanisms of NCM-811 Cathodes in Lithium-Ion Batteries Studied by X-ray Diffraction and Other Diagnostics / Friedrich, F., Strehle, B., Freiberg, A. T., Kleiner, K., Day, S. J., Erk, C., Gasteiger, H. A. / Journal of The Electrochemical Society, (2019), 166(15), A3760 - DOI

- Operando Identification of Liquid Intermediates in Lithium–Sulfur Batteries via Transmission UV–vis Spectroscopy / He, Q., Freiberg, A. T., Patel, M. U., Qian, S., & Gasteiger, H. A. / Journal of The Electrochemical Society, (2020), 167(8), 080508. - DOI

Potentiostats are used to apply defined voltage curves (and therefore also current curves) to the systems under investigation, in particular alternating voltages (or currents) of frequencies between 1 mHz and 3 MHz. By applying an alternating voltage of various frequencies to an electrochemical cell, electrochemical impedance spectroscopy (EIS) allows to characterize various (electro)chemical processes. In our lab, self-made battery cells are exposed to customized charge-discharge procedures also including impedance spectroscopy measurements.

Battery cyclers are potentiostats which allow to apply constant voltages or currents in order to cycle battery cells. In customized charge-discharge procedures, the (long-term) performance and the rate capability of self-made battery cells is investigated, either at room temperature or at elevated temperatures, in order to investigate lifetime and power density of batteries. In our lab, around 250 batteries can be investigated simultaneously.

With a Thinky planetary mixer, we prepare slurries of active material to be coated on metal foil with a defined wet film thickness. From this coating, we punch out electrodes to be used in batteries testing.

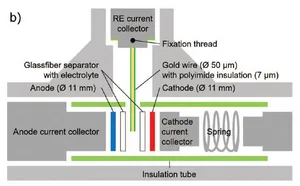

Highlights:

- Impedance spectroscopy is a powerful tool to investigate the electrode/electrolyte interface in Li-ion batteries

- Our gold-wire micro-reference electrode (GWRE) allows to deconvolute the impedance contributions from anode and cathode

- Long-term stability of the reference electrode is suitable to monitor electrode degradation upon continued battery operation >100 cycles

- Centric positioning of the reference electrode in the cell reduces bias and erroneous conclusions from impedance data

References:

- A Gold Micro-Reference Electrode for Potential and Impedance Measurements in Lithium Ion Batteries / Solchenbach, S.; Pritzl, D.; Kong, E.; Landesfeind, J ; Gasteiger, H. A. / J. Electrochem. Soc., 163(10), A2265-A2272 (2016)

- An Analysis Protocol for Three-Electrode Li-Ion Battery Impedance Spectra: Part I. Analysis of a High-Voltage Positive Electrode / Landesfeind, J. ; Pritzl, D. ; Gasteiger, H. A. / J. Electrochem. Soc., 164 (7), A1773 - A1783 (2017)

- Analysis of Vinylene Carbonate (VC) as Additive in Graphite/LiNi0.5Mn1.5O4 Cells / Pritzl, D. ; Solchenbach, S. ; Wetjen, M. ; Gasteiger, H. A. / J. Electrochem. Soc., 164 (12), A2625 - A2635 (2017)

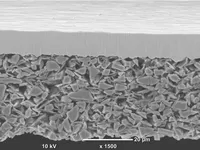

Methods and Equipment for Material Characterization

The cryo cross section polisher (IB-19520 CCP, JEOL) is the ideal device to prepare samples for scanning electron microscopy (SEM). An argon ion beam allows for smoother cross sections with less distortion compared to mechanical polishing methods for various kind of samples. Sensitive samples can additionally be cooled down with liquid nitrogen during polishing. To achieve the best results, varying polishing settings can be adjusted to the sample type.

Highlights:

- Clean polished cross section of hard, soft, and composite material

- Preparation of LIB electrode and MEA cross sections for SEM analysis

- Cryo-polishing to minimize beam damage for sensitive materials (e.g., binder etc.)

DRIFTS (Diffuse Reflectance Infrared Fourier Transform Spectroscopy) is a highly sensitive tool to assess the surface composition of electrode materials, e.g., NMC-based cathode active materials. Species like hydrates, carbonates and sulfates can be studied semi-quantitatively to gain understanding about the quality and purity of active materials. Thanks to an air-tight sample chamber (Harricks Scientific Products Inc., USA), materials can be characterized under inert conditions. The chamber is equipped with an inlet and an outlet valve to exchange the gas atmosphere or to perform operando studies on the reactivity of active materials.

Highlights:

- In-situ measurement of heat evolved by a battery during cycling or due to self-discharge

- High sensitivity (µW) and good time resolution

- Time-resolved quantification of heat sources in the battery system

- Characterization of the energy efficiency of active materials during cycling

- Cooperation with the Chair for Electrical Energy Storage of Prof. Jossen in the framework of the Aqua HysKaDi project

Mercury intrusion porosimetry (MIP) is used to examine the pore structure of a sample. Since mercury does not wet most substances (contact angle greater than 90°), it has to be forced to fill open pore space by applying an external pressure. According to the Washburn equation, this pressure correlates inversely to the pore diameter, which can be accessed from roughly 200 µm down to 3 nm by MIP. The more than five-decade span of pore sizes enables the application for a wide range of powders (e.g., cathode active materials for lithium-ion batteries) and solids (e.g. battery electrodes, catalyst layers and gas diffusion media of fuel cells and electrolyzers). Targeted parameters are the pore size and its distribution, pore volume, bulk and skeletal density, and finally the porosity of the sample.

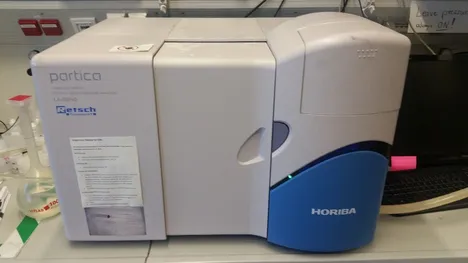

The Particle Sizer employs Mie scattering theory to determine particle size distributions of particles between 10 nm and 3 mm using two different light sources, a 650 nm laser diode and a 405 nm LED lamp. The required sample ranges between 10 mg and several grams depending on the material. We primarily use the particle sizer to measure size distributions of commercial cathode and anode active material particles but also for self-synthesized compounds.

Photomultiplier-setup with measurement chamber for optical cell (dark box) and photomultiplier tube unit connected to gated photon counter (computer). Using the photomultiplier-setup, the singlet oxygen production of cathode active materials for Li-ion batteries is measured qualitatively and quantitatively. To simulate the aging of cathode active materials, the delithiated cathode active material is heated, which releases the oxygen.

The Anton Paar MCR 302 rheometer enables us to characterize the rheological properties of battery slurries such as the flow at the coating shear rate and quantify shear-thinning behavior in order to prepare suitable slurry recipes for a reproducible industrially standardized coating process. Furthermore, we can measure viscosities of solvents and electrolytes used in batteries and for rotating disc measurements.

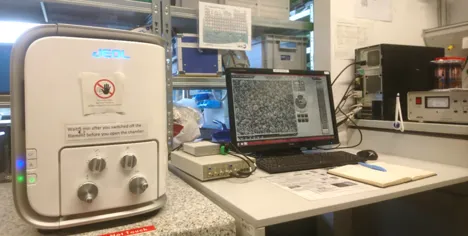

The table-top SEM Jeol JCM6000 (left-side) with the possibility of gold-sputtering with Jeol JFC-1300 (right side) is located at TEC. The SEM is a useful tool to visualize the micron sized active material particles in battery electrodes. Additionally the composition of the electrode can be determined via elemental analysis using the built-in EDX probe.

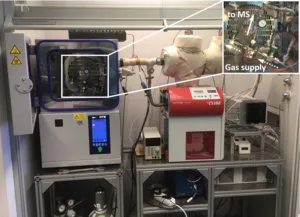

Highlights:

- Quantitative investigation of material properties under a variety of atmospheres such as CO, N2, Ar, H2, O2 or synthetic air and switching of reactive gas during an experiment

- Simultaneous analysis of the gaseous decomposition products via mass spectrometer (TGA-MS)

- Heat flow analysis using a differential scanning calorimetry (DSC) module

References:

- Li2CO3 Decomposition in Li-Ion Batteries Induced by the Electrochemical Oxidation of the Electrolyte and of Electrolyte Impurities / Freiberg, A. T. S.; Sicklinger, J.; Solchenbach, S.; Gasteiger, H. A.; Electrochim. Acta, 2020, 346, article # 136271

- Ambient Storage Derived Surface Contamination of NCM811 and NCM111: Performance Implications and Mitigation Strategies / Sicklinger, J.; Metzger, M.; Beyer, H.; Pritzl, D.; Gasteiger, H. A. / J. Electrochem. Soc., 2019, 166(12), A2322-A2335

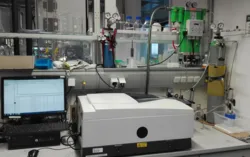

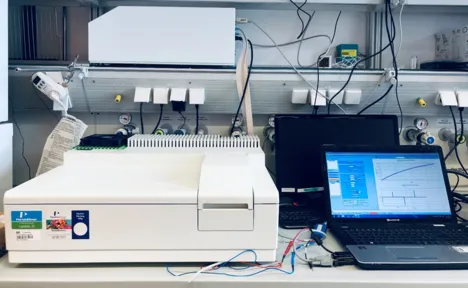

Ultra-Violet spectroscopy (UV-Vis) is a practical technique to detect any chromophore, which interacts with the incident beam in the wavelength region of 200- 1100 nm (Lambda 35).

In order to gain insight into the reaction mechanism of a battery system with chromophoric species involved, it is necessary to detect the possible chromophoric reaction intermediates that are generated during battery cycling (such as polysulfides in Lithium-Sulfur batteries). A special designed spectroelectrochemical cell (pouch-cell based design) was developed in our group, which is able to demonstrate a rigorous electrochemical performance. By comparing the obtained operando spectra with reference UV-Vis spectra, we are able to monitor the chromophoric reaction intermediates both qualitatively and quantitatively in an operating battery-cell.

X-ray photoelectron spectroscopy (XPS) is a surface-sensitive quantitative spectroscopic technique. With this method, it is possible to quantify the elemental composition, empirical formula, chemical state and electronic state of the elements that are within a range of ~5 nm of the surface.

In the battery research, XPS (here: Kratos Axis Supra) facilitates the identification of the composition of surface layers such as the solid-electrolyte interphase (SEI) on anode materials and of adsorbates on the cathode active material as well as changes in the structure of cathode materials. The device provides a heated sample holder to mimic the influence of temperature as well as argon sputtering gun to expose deeper layers.

X-ray powder diffraction (XRD) is an analytical technique used for phase identification of a crystalline material and can provide information on unit cell dimensions. Operando measurements in pouch-cell setups allow to determine structural properties and transformations of active materials during cycling.