Negative Electrode (Anode)

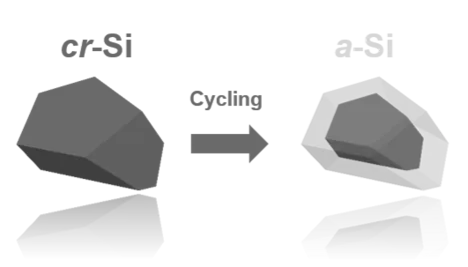

The anode research focuses on processes of the intercalation material graphite and (de-)alloying material silicon. The anode acts as a host material for lithium and plays an important role on cycling performance and battery lifetime. Thus, we investigate degradation mechanisms on the material level, such as morphological changes of silicon particles, as well as the buildup of an effective solid electrolyte interface (SEI) and its changes upon cycling.

Our interests:

- Monitoring structural changes of Si-particles (e.g., partial amorphization) with varying cycling conditions

- Understanding the mechanism and effect of novel solvent additives on anode materials

- Evaluating methods, such es pre-lithiation, to increase the cycling performance of silicon anodes

Contact person: Jonas Dickmanns

Recent publications:

- Effect and Progress of the Amorphization Process for Microscale Silicon Particles under Partial Lithiation as Active Material in Lithium-Ion Batteries / M. Graf, C. Berg, R. Bernhard, S. Haufe, J. Pfeiffer, H. A. Gasteiger, J. Electrochem. Soc. 2022, 169, 020536 - DOI

-

Quantifying the Distribution of Electrolyte Decomposition Products in Silicon-Graphite Electrodes by Neutron Depth Profiling / M. Wetjen, M. Trunk, L. Werner, R. Gernhäuser, B. Märkisch, Z. Révay, R. Gilles, H. A. Gasteiger / J. Electrochem. Soc., 2018, 165(10), A2340-A2348 - DOI

-

A Liquid Electrolyte-Based Lithium-Ion Battery Cell Design for Operando Neutron Depth Profiling / F. Linsenmann, M. Trunk, P. Rapp, L. Werner, R. Gernhäuser, R. Gilles, B. Märkisch, Z. Révay, H. A. Gasteiger / J. Electrochem. Soc., 2020, 167(10), 100554 - DOI

Positive Electrode (Cathode)

The cathode active material traditionally used in commercial Li-Ion battery is a layered lithium metal oxide. This ternary system delivers high energy densities over a long cycle life. Unfortunately, these materials are thermodynamically limited and only 75 % of the containing Li can be used, which intrinsically limits the energy density of these materials. The crystal lattice collapses if more Li is removed and the cycle performance is diminished. Our group is focusing on understanding the effects at play during this decomposition. Furthermore, new classes of cathode active materials are also investigated which offer higher energy densities while suffering from poorly understood stability issues, such as release of singlet oxygen. Our lab investigates and characterizes the mechanism at play with a mixture of commercial cell cycling, highly adapted cell design and spectroscopic analysis.

Our interests:

- Characterization of next generation cathode materials (Ni-rich or Li-/Mn-rich NMC, LNMO) with operando analytical techniques (OEMS, XRD, XAS, EIS)

- Optimization of commercial calcination and washing steps

- Surface stabilization of cathode active materials by generating a resilient protection layer

Contact person: Tim Kipfer

Recent publications:

- SO3 Treatment of Lithium- and Manganese-Rich NCMs for Li-Ion Batteries: Enhanced Robustness towards Humid Ambient Air and Improved Full-Cell Performance / Sicklinger, J.; Beyer, H.; Hartmann, L.; Riewald, F.; Sedlmeier, C.; Gasteiger, H. A. / J. Electrochem. Soc., 2020, 167, 130507 (Open Access) - DOI

- Enhancement of Electrochemical Performance of Lithium and Manganese-Rich Cathode Materials via Thermal Treatment with SO2 / Sclar, H.; Sicklinger, J.; Erickson, E. M.; Maiti, S.; Grinblat, J.; Talianker, M.; Susai, F. A.; Burnstein, L.; Beyer, H.; Hartmann, L. Avruschenko, G.; Gasteiger, H. A.; Markovsky, B.; Aurbach, D. / J. Electrochem. Soc., 2020, 167, 110563 (Open Access) - DOI

- A Liquid Electrolyte-Based Lithium-Ion Battery Cell Design for Operando Neutron Depth Profiling / Linsenmann, F.; Trunk, M.; Rapp, P.; Werner, L.; Gernhäuser, R.; Gilles, R.; Märkisch, B.; Révay, Z.; Gasteiger, H. A. / J. Electrochem. Soc., 2020, 167, 10 (Open Access) - DOI

All-Solid-State-Batteries (ASSB)

All-solid-state lithium-ion batteries (Li-ASSBs) are regarded as promising candidates for the next generation of energy storage systems for electric vehicles and mobile devices. ASSBs offer potentially higher energies densities due to the usage of Li-metal as anode material and higher safety due to the non-flammability of many solid electrolytes compared to the state of the art Li-ion batteries (LIBs) with flammable organic electrolytes. At TEC, we investigate the complete variety of ASSBs from material characterization of new solid electrolytes to cell manufacturing in different cell designs (e.g., pressure cells and pouch cells)

Our interests:

- Development and validation of cell setups for high pressure impedance analysis

- Preparation of all-solid-state lithium-ion battery cells

- Characterization of the solid electrolyte/lithium interface as well as the cathode electrolyte interface (CEI)

Contact person: Per Håkon Pedersen Finne

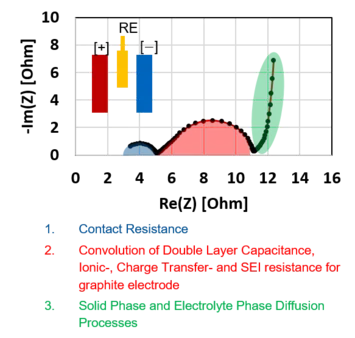

Kinetic & Transport Parameters

For an accurate simulation of lithium-ion batteries, a large number of model parameters is needed. At TEC we developed measurement techniques and cell designs to measure a large number of these parameters, especially geometric parameters of porous electrodes, the kinetics of battery active materials as well as electrolyte transport parameters.

Our interests:

- Understanding the limitation of porous electrodes

- Direct experimental determination of transport parameters in different electrolytes

- Development of new experimental setups for parameter determination

Contact person: Simon Helmer

Recent publications:

-

Methods - Understanding Porous Electrode Impedance and the Implications for the Impedance Analysis of Li-Ion Battery Electrodes / Morasch, R.; Keilhofer, J.; Gasteiger, H. A. and Suthar, B. / J. Electrochem. Soc. (2021), 168 (Open Access) - DOI

-

Method to Determine the In-Plane Tortuosity of Porous Electrodes / Suthar, B.; Landesfeind J.; Eldiven, A.; Gasteiger, H.A. / J. Electrochem. Soc., 2018, 165(7), A2008-2018 (Open Access) - DOI

- Influence of the Binder on Lithium Ion Battery Electrode Tortuosity and Performance / Landesfeind, J.; Eldiven, A.; Gasteiger, H. A. / J. Electrochem. Soc., 2018, 165(5), A1122-A1128 (Open Access) - DOI

- Temperature and Concentration Dependence of the Ionic Transport Properties of Lithium-Ion Battery Electrolytes, J. Landesfeind and H. A. Gasteiger, J. Electrochem. Soc., vol. 166, no. 14, pp. A3079–A3097, Sep. 2019, - DOI

Process Technology & Scale-Up

The manufacturing of battery cells is a multi-step process, including mixing of electrode materials, coating, calendering, drying, cell confectioning, electrolyte filling and formation. At TEC, we investigate the cell manufacturing process in close collaboration with the Institute for Machine Tools and Industrial Management (iwb). We transfer lab scale developed process parameters for new materials to the iwb pilot production line and study the influence of up-scaled production and cell and material properties with several diagnostic methods.

Our Interests:

- Studies on the mechanical and electrical properties of the electrodes manufacturing process

- Gassing behavior depending on cell geometries, electrolytes and the formation process

- Pressure and temperature difference in lab cells and multilayer pouch cells and their influence on the material and cell performance

Contact person: Philip Rapp