Abstract of the full text available here:

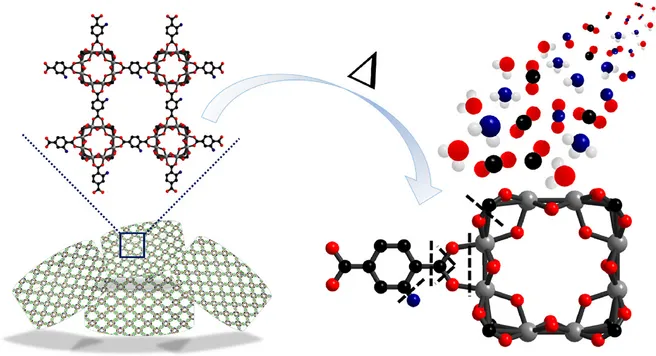

Titanium based metal-organic frameworks (MOFs) are interesting self-sacrificial precursors to derive semiconducting porous nanocomposites for highly efficient heterogeneous catalysis. However, there is a lack of systematic and in-depth mechanistic understanding of the pyrolytic conversion of MOF precursors into the desired functional composite materials. In this work, TGA-MS and in situ STEM/EDX combined with other characterization techniques were employed to investigate the evolution of the structural, physicochemical, textural and morphological properties of NH2-MIL-125(Ti) pyrolysis at different temperatures in an inert gaseous atmosphere. In situ thermal analysis of NH2-MIL-125(Ti) reveals the presence of 3 rather defined stages of thermal transformation in the following order: phase-pure, highly porous and crystalline MOF → intermediate amorphous phase without accessible porosity → recrystallized porous phase. The three stages occur from room temperature till 300 °C, between 350 and 550 °C and above ∼550 °C respectively. It is found that the framework of NH2-MIL-125(Ti) starts to collapse around 350 °C, accompanied with the cleavage of coordination and covalent bonds between organic linkers [O2C–C6H3(NH2)–CO2]6 and the Ti oxo-cluster Ti8O8(OH)4. The organic linker continues fragmentation at 450 °C causing the shrinkage of particle sizes. The dominant pore size of 0.7 nm for NH2-MIL-125(Ti) gradually expands to 1.4 nm at 800 °C along with the formation of mesopores. The derived disc-like particles exhibit an approximately 35% volume shrinkage compared to the pristine MOF precursor. Highly crystalline N and/or C self-doped TiO2 nanoparticles are homogeneously distributed in the porous carbon matrix. The original 3D tetragonal disc-like morphology of the NH2-MIL-125(Ti) remains preserved in derived N and/or C doped TiO2/C composites. This study will provide an in-depth understanding of the thermal conversion behavior of MOFs to rationally select and design the derived composites for the relevant applications.