Research

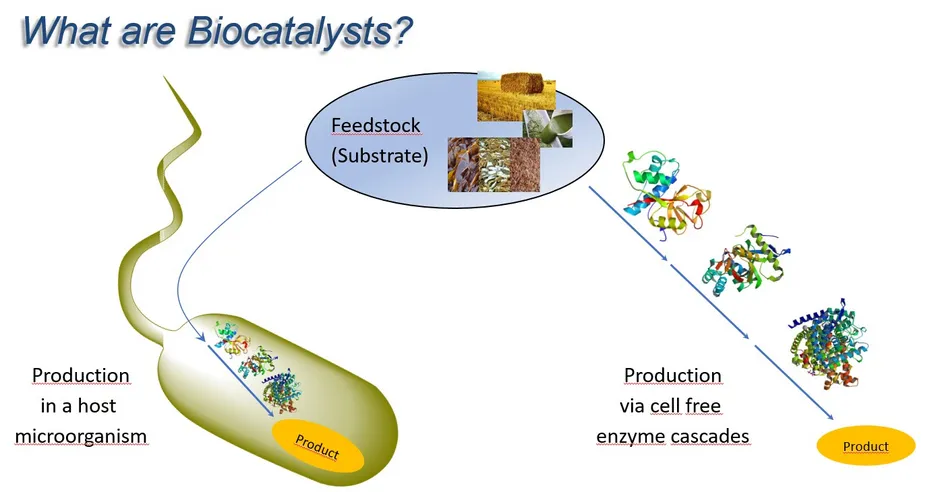

The research of the Werner Siemens-Chair of Synthetic Biotechnology is focused on fundamental aspects of biocatalysis and genetic engineering to understand and predict the basic molecular and structural features that provide or impose industrial process fitness on biocatalytic systems.

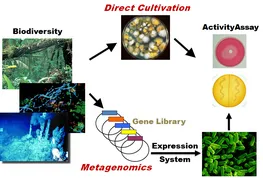

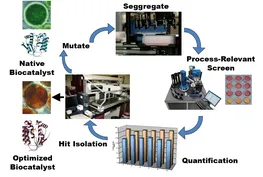

Research involves biocatalytic aspects of biomass transformation into building blocks for chemical, pharmaceutical, food and energy production. Cores themes are the isolation, characterization and process relevant optimization of novel biocatalysts utilizing modern genomics and proteomics tools. Additionally, we use the comprehensive toolbox of synthetic biology to create process tailored whole cell biocatalysts for transformation of biomass into value adding products. Associated with these efforts is the development of research tools for the utilization and optimization of phototrophic organisms that combine remediation of CO2 greenhouse gas effects with the production of value-adding product streams.

Technology

- Metagenomics

- Proteomics

- Strain Optimization

- High Throughput (HT) Assay Development

- Instrumental Analytics

The research is manifested by three pillars:

1. Algae Biotechnology for the energy, chemical, construction and food sector

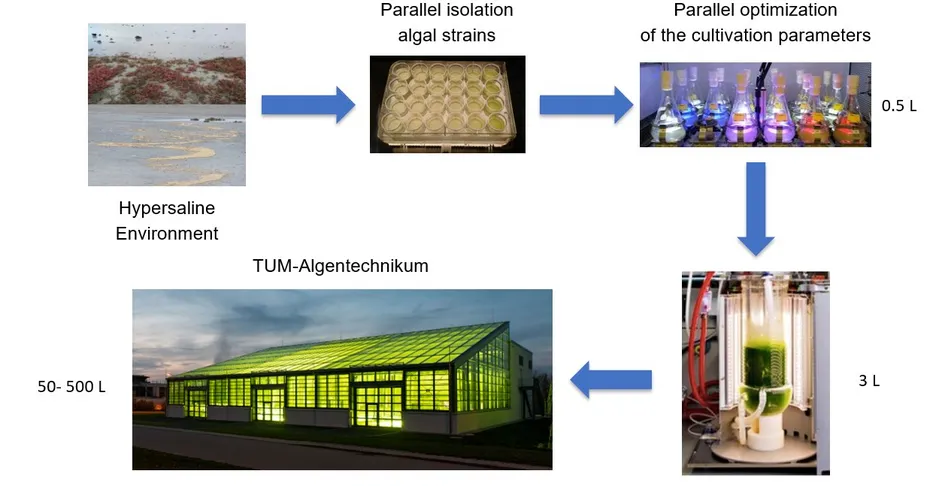

Microalgae are the most efficient biotechnology tools for photosynthetic conversion of the greenhouse gas CO2 into value adding chemical products. The Brück group has sustained algae centered research activities, that focus production of aviation biofuels, sustainable carbon fibers, recycling of rare earth -and precious metals from waste water and production of purified algae proteins for human food production. In this context, Brück covers activities from algae identification, screening (lab) and cultivation (lab to technical 500L scale in the TUM AlgaeTech Center) to the isolation and qualification of algae based products. Most projects are carried out with international academic and industrial partners (i.e. www.tum-create.edu.sg/research/proteins4singapore). The research activities have lead to numerous papers and patents, where particularly the production of algae based carbon fibers lead to global attention with a citation in the IPCC1.5 report (https://www.ipcc.ch/sr15/), as an industrially relevant carbon sink and the formation of the start-up CleanCarbon Technologies GmbH, that is commercializing the technology portfolio. The algae based carbon fibers technology provides a CO2 negative and energy saving route for production of this lightweight, high performance material, that cannot be achieved otherwise. The material offers a route for building lightweight CO2 neutral cars, planes and houses powered by electricity or biofuels. Hence the technology is a milestone towards decarbonizing the global mobility and building sector. Further, the algae technologies developed by the Brück group are all scalable and provide a route to create value from greenhouse gases linked with positive impacts on terrestrial and marine ecosystems, as exemplified by the algae based metal recycling technology, which prevents metal leaching in the global ecosystem, where they can induce toxic effects on organisms. The production of algae proteins for human food application further fosters the resilience of the global food system to climate change effects and provides answers to feeding a still growing human population. The algae centered research of the Brück group addresses SDG’s 2-4,6, 7-15.

2. Microbial oil (yeast) oil production:

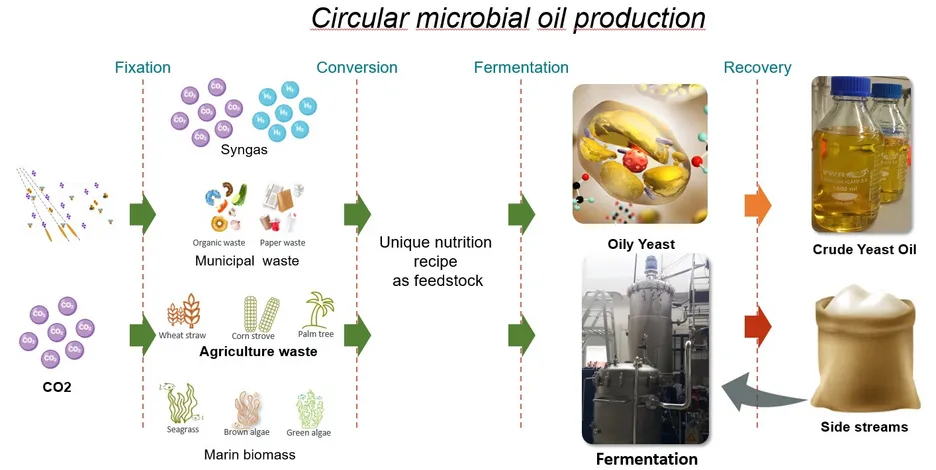

Plant oil (triglycerides), such as palm, rapeseed and cocoa butter oil are highly desired first-generation feedstocks for the food, chemical, cosmetics, pharmaceutical and biofuels industry. Specifically, tropical plant oil, such as palm oil and cocoa butter are associated with significant land use change, tropical forest destruction, negative effects biodiversity as well as child/slave labor. Climate change induced effects lead to a reduction of agricultural land and enhanced plant disease incidence, leading to reduced plant oil yield and increasing market prices posing a supply chain risk to various industry sectors. Microbial oils, such as yeast oil can alleviate this situation. Yeast oil can be cultivated by industrially established fermentation technologies without demand for agricultural land and negative effects on ecosystems and biodiversity. Moreover, yeast oil production is independent on climate change effects and be produced almost anywhere in decentralized unit operations. The Brück group is a global leader in yeast oil production. Brück has devised a completely new, circular bioprocess for yeast oil production, that enables high space-time and total yields without generation of waste streams. The yeast is first grown on a sugar rich biomass hydrolysate, which is generated from various biomass waste streams (i.e. wood residue, cereal straw/ bran, waste bread or black liquor from paper pulping). A proprietary nutrient feeding strategy allows for simultaneous production of biomass and intracellular oil for the first time, which allows biomass harvest after 3 days. Depending on the process conditions, this process generates a palm, rapeseed oil or cocoa butter equivalent with the same chemical and physical properties as the plant sources. The Brück group then deploys a proprietary enzyme formulation, that lyses the yeast cell wall and allows yeast oil recovery by simple centrifugation. While the resulting oil can be directly processed in various applications (i.e. food, biofuel, cosmetics), the remaining cell wall debris is recycled in the next fermentation batch. The process uses wild type yeast for food and cosmetic application to circumvent regulatory limitation. Hence the process, is GMO free, does not use any organic solvents for product recovery and does not generate any waste streams. The Brück devised FHCR process reduces production costs by 85% compared to conventional yeast oil processes. Moreover, the Brück process has a superior land and greenhouse gas efficiency as production on 1ha industrial land generates as much yeast oil as can be produced as on 80.000 ha Oil Palm monoculture, thereby saving 16 Mio. metric tons of CO2 equivalents in greenhouse gases. This technology portfolio was the basis for the formation of Global Sustainable Transformation GmbH (https://gstransform.de/en/), which is now providing global B2B solutions for yeast oil production to industry clients, that are valorizing internal or external biomass streams. The technology is therefore a stepping stone towards a circular bioeconomy. The microbial oil centered research of the Brück group addresses SDG’s 2,4,6, 7-15

3. Designer cells for sustainable production of bioactive compounds

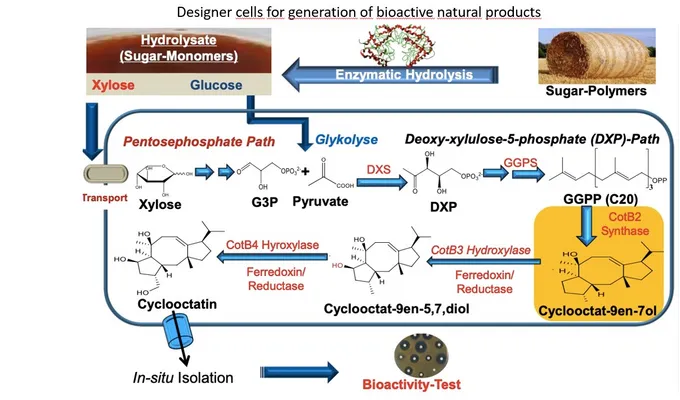

In the last 30 years about 50% of all clinically relevant drugs have been derived from natural products. This number is significantly increased if we add aroma and nutraceutical compounds, that contribute to human wellbeing and health. In this context, terpenes are the most numerous and structurally diverse family of natural products (i.e. artemisinin and taxol). Most terpenes, are secondary metabolites being present in minute quantities in the natural source (i.e. plant, animal). Therefore, natural harvest and extraction for industrial use is costly and associated with negative ecosystem impacts. Moreover, these compounds commonly feature chemically complex structures, that require lengthy, costly chemical synthesis associated with toxic waste streams and high energy conversion steps. A sustainable solution to access these bioactive compounds is the recombinant production in metabolically streamlined microbial hosts, such as E. coli or baker’s yeast. Transferring the genetic machinery from the natural source (plant, animal) to the microbial host enables cost efficient, targeted production of the desired compounds using industrially established fermentation technology without toxic side streams.

Over the last decade the Brück group has identified new biosynthetic gene clusters encoding unique bioactive natural products, enabling sustainable production of bioactive compounds in microbial hosts. Further, application of advanced bioinformatic and structural biology tools allowed mechanistic characterization of key terpene synthase enzymes, that are gatekeepers in recombinant terpene bioproduction. The Brück group used this information for targeted genetic manipulation of terpene synthases to generate non-natural products, that have alternative bioactivities, broadening the product and application scope of the original compound class. One of the hallmark achievements was the recombinant production of isoelisabethatriene, a precursor of pseudoptosis with antibacterial and anti-inflammatory activities. Pseudopterosins have current applications in the cosmetic sector. However, these compounds have been harvested non-sustainably from the Caribbean, marine soft coral Antillogorgia elisabethae, thereby destroying coral reef that are a major natural carbon sink and biodiversity hot spot. Brück’s synergistic combination of synthetic- and systems biology methodologies together with advanced bioinformatic tools are a major step towards the scalable and sustainable production of Pseudopterosins, which would protect corals reef systems and its sensitive marine biodiversity, which is a yet underexploited treasure trove for new bioactive compounds. The technology has been patented and is currently en-route to commercialization, complying with UN SDG’s 3, 12, 13, 14 and 15.

4. Fungal Biotechnology

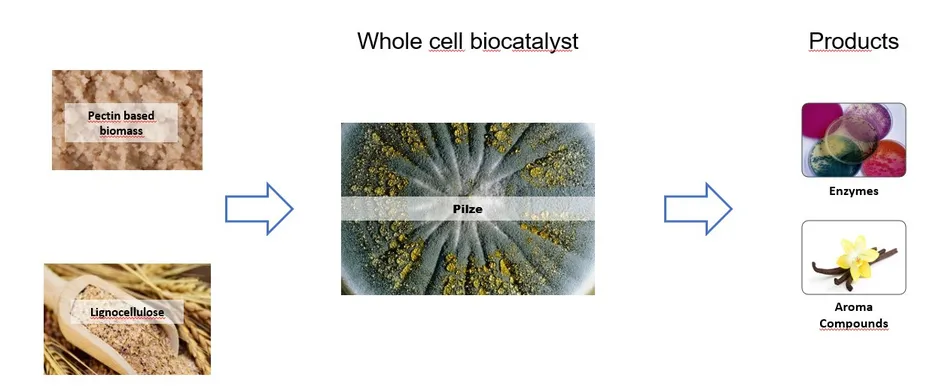

Filamentous fungi are the microbial recycling machinery in nature, responsible for degrading and recycling biomass. The ecological interactions of fungi with other organisms and organic matter in terrestrial and marine ecosystems are complex and yet underexplored. The Brück group isolates and characterizes new fungi from complex environmental samples with respect to their hydrolytic enzyme activities and potential to generate bioactive natural products and aroma compounds. A prime research focus is the production and molecular characterization of new hydrolytic enzyme activities, that enable us to hydrolyse (liquify) complex polymeric sugars, such as cellulose, pectin and chitin contained in biogenic streams like municipal sewage sludge, wood chips, cereal straw and mushroom cultivation waste or yet unexplored biomass waste streams. The resulting biomass hydrolysates containing fermentable sugars are used as fermentation media in microbial fermentations described in the sections 1-3. Moreover, cultivation of the proprietary fungal strains generates aroma compounds when cultivation on complex biomass waste streams. These volatile compounds are captured and liquified during the fungal cultivation and can be used as aroma and flavoring compounds in food and cosmetic applications. The residual fungal mycelium is utilized as an isolation material in sustainable building applications. The fungal centered technologies of the Brück group address SDG’s 2,4,6, 7-15.

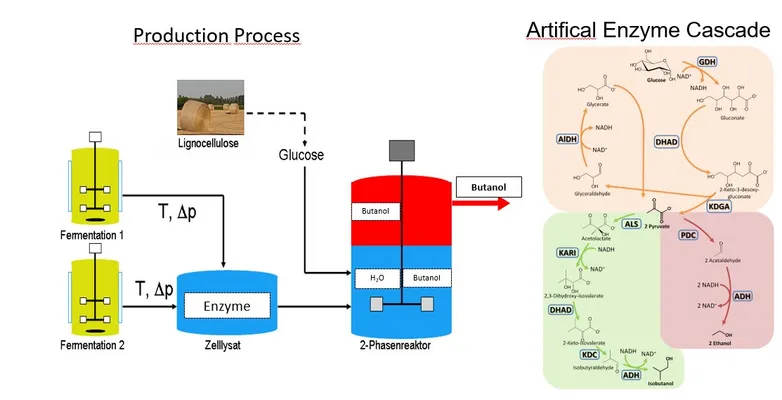

5. Cell free production systems for generation of renewable chemicals

Not all chemicals compounds can be generated at industrially relevant titers in controlled bioreactor systems using whole cell biocatalysts. This pertains particularly to compounds, that at elevated titers become toxic to cellular systems, are poorly soluble in water or rely on gaseous educts. Examples are production of medium chain length alcohols (i.e. butanol, hexanol) and fatty acid derivatives (i.e. fatty alcohols, wax- esters), which are toxic to the production organisms and/ or water insoluble at higher concentrations. To access these compounds, the Brück group applies bioinformatic driven ab-initio design principles to generate natural and artificial enzyme cascades, which free the biocatalytic system from the boundary conditions of a cellular system.

Where required individual enzyme activities are subjected to targeted mutagenesis or direction evolution to adapt or improve their activities towards a desired substrate or process condition. This process involved sophisticated high throughput selection methodologies, that require the extensive robotic infrastructure, such as automated pipetting platforms, colony picking robots and nano-droplet screening platforms available at the Brück group. An example for artificial cascades is the conversion of lignocellulose derived sugars into isobutanol, which is a platform chemical in the chemical and biofuels sector. The cell free process technologies of the Brück group address SDG’s 2,4,6, 7, 9, 11, 13-15.