Development of Prediction Models for Adhesive Performance Using Multivariate Data Analysis of Spectroscopical and Physical Properties

Objectives

- Development of non‑destructive, vibrational spectroscopy-based analysis methods for adhesives under varying environmental conditions

- Multivariate combination of spectroscopic results with destructive lap-shear tests

Methods of Approach

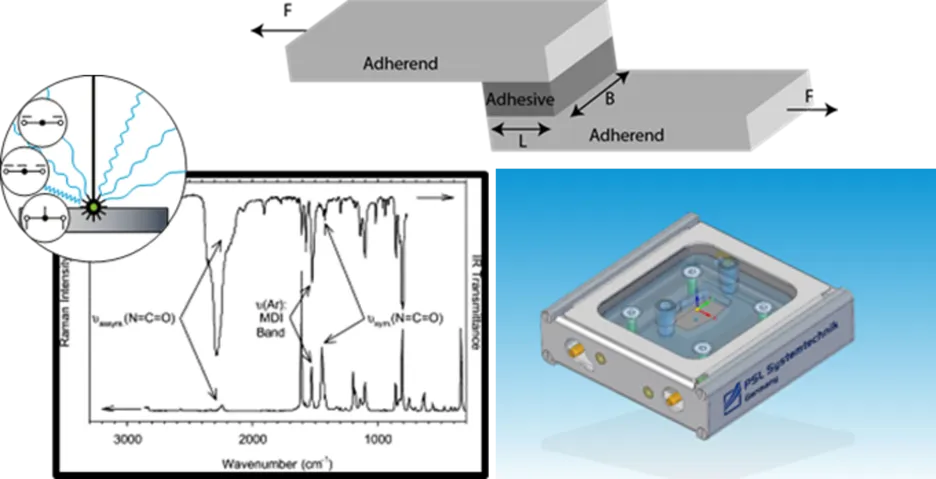

- Raman and Infrared (IR) spectroscopy

- Differential scanning calorimetry

- Lap-shear test

Description

Adhesive bonding is widely used in industrial practices to join two separate parts (the adherends) together using polymeric material (the adhesive). Due to their increasing use in several branches of industry, i.e. the automotive industry, the global market for adhesives reached 60 billion US Dollars in 2021 and is expected to grow by around 5 % year on year to over 100 billion dollars in the coming decade.

The cohesive strength of the adhesive is most commonly tested using the lap-shear test, which can be performed in several variations. However, as this test is destructive and usually not performed on the real components, it is not representative of reality. Therefore, the development of a non‑destructive, in‑line measurement technique would be most advantageous.

This study will begin the development of this measurement technique. For this, the chosen adhesive will be cured under varying environmental conditions (temperature, humidity, etc.) and the polymerisation tracked via IR and Raman spectroscopy. The changes of the curing environment should be visible in the spectra, with the amount of side reactions and termination reactions changing. These changes in the polymer composition detected via the vibrational methods should also result in different cohesive strengths in the lap-shear test. Combining the destructive and non-destructive methods, would allow for prediction models to be developed from which we can predict the cohesive strength of the adhesive using only the non-destructive vibrational spectroscopic methods.

Publications

A. Thomas, J. Gehrlein, S. Kaufmann, D. Huber, N. P. Ivleva, Comparative Study into the Impact of Varying Curing and Test Conditions on the Strength and Failure Modes of Adhesives for Realistic Use Case Scenarios, The Journal of Adhesion 2025, doi.org/10.1080/00218464.2025.2495883