Analysis of (Organic) Filmic Impurities on Metallic Surfaces via Surface Enhanced Raman Scattering (SERS)

Objectives

- Analysis of the molecular composition of filmic organic impurities on (metallic) surfaces using SERS

- Approach to SERS‑based chemical imaging (CI)

- Comparison of developed and established methods

Methods of Approach

- Surface-enhanced Raman scattering (SERS)

- Infrared (IR) spectroscopy

- Fluorescence spectroscopy

- Laser-induced breakdown spectroscopy (LIBS)

Description

Technical Cleanliness (TecSa) is a field of essential significance in the automotive industry. With the accelerated growth of e‑mobility and the related transition from combustion engines to high‑voltage battery packs, the TecSa‑requirements for components have strongly gained importance.

One of the hazardous issues is the presence of particles in the µm‑range, e.g. stemming from packaging material, dust or abrasion from components. Especially metallic particles are problematic, as conductive material between battery cells or other electrified components can lead to short‑circuit faults and, in the worst case, thermal events.

Filmic organic impurities on parts’ surfaces play a critical role in the abundance of particulate matter. Organic films originating in oils, fats or other lubricants can lead to the formation of metallic particles and additional material defects during welding processes. Also, the cleanup of the affected surfaces from particles is hindered by the presence of mentioned films. Additionally, the organic impurities can hinder the functionality of adhesives, which are commonly needed for the connection of parts. Therefore, it is of great importance to ensure the absence of filmic impurities and particles before further treatment of the respective elements.

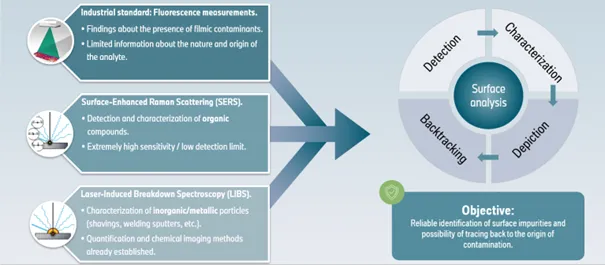

The most used method for the detection of filmic impurities is based on fluorescence measurements. A big disadvantage of this method is the necessity of knowledge which substance to expect, as it is limited in the determination of the molecular structure of the analyte. Additionally, surfaces with background fluorescence allow no clear differentiation between analyte and surface.

In this project, the analysis of filmic impurities is approached via Raman spectroscopy and SERS for increasing the limited sensitivity of conventional Raman spectroscopy. The presence of Ag‑ or Au‑nanoparticles within the analyte film is used to induce an intensified signal by localized surface plasmon resonances in the metallic nanostructures. Therefore, a highly sensitive method with additional information about the molecular structure is expected. With the help of existing databases, the exact type of impurity and its origin can then be determined.

Combining this approach with the results of established LIBS methods of inorganic/metallic particles on the respective surface and further chemical imaging can generate a powerful and extensive tool for the analysis of TecSa‑critical surfaces in the automotive industry.

As a conclusion of this project, Raman spectroscopy and SERS are used for the analysis of filmic, organic impurities on the surface of automotive parts. The objective is to develop a method with high sensitivity and the possibility to characterize impurities to determine their origin with the possible addition of chemical imaging. As a result, the method shall be used to help meet the high TecSa‑requirements of the production in e-mobility.