Metallic Particle Characterization in the Context of Technical Cleanliness in Electrified Drive Systems by Laser-Induced-Breakdown-Spectroscopy (LIBS)

Objectives

- Development of LIBS quantification models for metallic particles of critical size

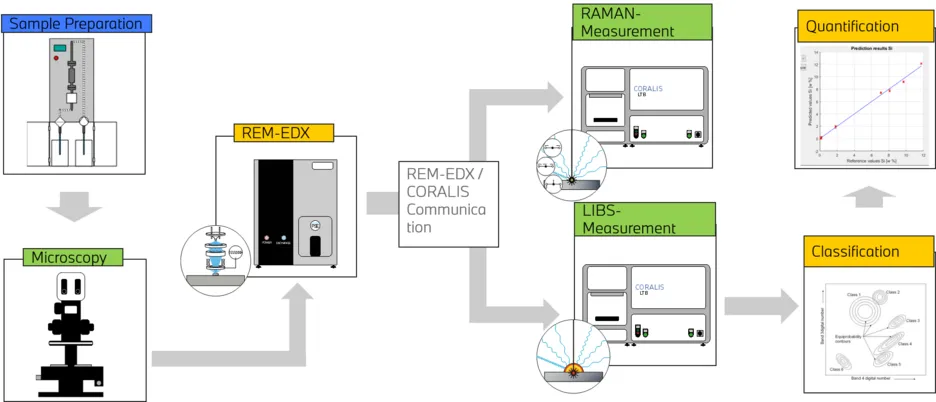

- Development of analytic steps to enable automated and fast particle analysis

- Exploring novel approaches for particle extraction in electrified drive systems

Methods of Approach

- Laser-Induced-Breakdown-Spectroscopy

- SEM-EDX

Description

In this study Laser-Induced-Breakdown-Spectroscopy (LIBS) is used in addition to optical microscopy and SEM-EDX-analysis to analyze metallic particles in the context of technical cleanliness electrified drive systems. LIB-Spectrometry is a powerful tool to provide detailed and adequate information about the particles’ chemical composition. Additionally, the material can be analyzed with only a minimum of sample preparation and short measurement times.

Electrified drive systems are manufactured to much tighter cleanliness tolerances than the conventional combustion engines. Unwanted contamination inside critical areas of an electrified engine or the energy storage systems can lead to less efficient engines and in some cases a complete engine failure.

Technical cleanliness (TecSa) analysis in the automotive industry investigates the presence of particles in general as well the particles’ source. To identify the root cause detailed material analysis is required.

In today’s standard technical cleanliness analytics, which is optimized for combustion engines, only, the particles’ size (e.g. optical microscopy) as well as their crude chemical composition is analyzed (e.g. SEM-EDX).

The findings in this project will be used for increasing the quality of produced electrified vehicles as well as for fast and efficient detection of problems during production.